Table of Contents

- What Is Considered a High-Viscosity Liquid?

- Common Industrial Applications

- Why High-Viscosity Fluids Are Difficult to Pump and Dispense

- Best Practices

- The Best Pumps for High Viscosity Fluids

- FAQs

Pumping high-viscosity materials is no easy task. They behave more like a paste than a traditional liquid and consequently can lead to a variety of problems during dispensing and application. Especially if you do not have the right equipment or are not following best practice for pumping high-viscosity materials, you could run into trouble.

With our experience in dispensing, we want to help. In this article, we share more information about high-viscosity materials, including tips and tricks, as well as recommendations for high-viscosity dispensing equipment.

What Is Considered a High-Viscosity Liquid?

Viscosity is a fluid’s resistance to flow and is measured in centipoise (cP). Materials with a lower centipoise (around 1 to 1,000 cP) are thinner and have a lower viscosity. A good example is water. Materials with a higher centipoise (50,000+ cP) are thicker with a higher viscosity. Heavy grease is an example.

What makes a liquid a high-viscosity liquid in dispensing is subjective. There is no single universal cutoff for what qualifies as a high-viscosity material. In industrial fluid dispensing, the term typically refers to materials that behave like a paste and are thick enough to require special considerations for inlet feeding, speed control, and pressure drop. The higher resistance to flow is usually intentional for its given application.

Higher-viscosity materials in dispensing can include epoxies, urethanes, silicones, thermal interface materials, and more. They often start in the tens of thousands of centipoises and up, depending on the application. In some cases, we have worked with materials over 800,000 centipoise.

Common Industrial Applications for High-Viscosity Materials

High-viscosity fluids are common in applications where the material needs to hold its shape, form a thicker coating, or fill gaps without slumping. They can be found across industries such as construction, transportation, electronics, and general industrial assembly.

Some common examples of applications where high-viscosity materials are used for industrial purposes include:

- Structural glazing or weathering sealing

- Crack filling for roadways and infrastructure repair

- Bonding, potting, and encapsulation

- Electronic and EV-related assemblies

- Aerospace manufacturing

- High-build protective coatings and corrosion barriers in industrial facilities

Why High-Viscosity Fluids Are Difficult to Pump and Dispense

Compared to low-viscosity materials that flow easily through equipment, high-viscosity materials resist flow. As viscosity increases, flow rates drop at the same pressure, pressure loss rises through long or narrow lines, and equipment must work harder to maintain consistent output.

Consequently, high-viscosity material dispensing generally requires significantly more pressure and energy to move the material through hoses, valves, and nozzles and maintain the same flow. This increased demand places more stress on the inlet, pump, and dispense point. This increased effort can strain pumps and increase wear on seals and motors. In some cases, it may even lead to inconsistent dispensing.

High-viscosity silicones are notoriously difficult to mix, particularly in two-component systems. In some cases, the catalyst is relatively thin, while the base material is significantly thicker. This imbalance can create feed and ratio challenges if the pumping system is not properly engineered for both sides of the material.

Another issue with high-viscosity fluid dispensing is that some of these materials are also temperature- and shear-sensitive. As a result, small changes in heat or mechanical stress can significantly alter their flow behavior. Without precise temperature control and properly matched pumping equipment, issues such as pulsation, air entrapment, bead inconsistency, and material waste can occur.

Best Practices for Pumping High-Viscosity Fluids

Pumping high-viscosity materials requires more than simply selecting a larger pump. High-viscosity fluid dispensing problems can include inconsistent bead sizes, surging, slow refill of pump chambers, or frequent maintenance. Even small setup mistakes can lead to major performance issues.

The good news is that many of these issues have practical fixes and can be avoided if you follow best practices. Before making major equipment changes, start with the fundamentals. We are sharing the top tips and tricks for pumping high-viscosity materials so you can avoid any major issues.

- Engineer the inlet first. Use the shortest, largest-diameter inlet path possible and eliminate restrictive fittings, tight bends, and undersized valves.

- Slow down before you scale up. Faster is rarely better with high-viscosity fluid dispensing. Thick materials often require lower RPM to properly fill pump chambers.

- Use follower plates or ram systems for drums and pails. These components can help reduce air pockets, improve material feed, and prevent cavitation.

- Apply positive inlet pressure when needed. Higher viscosity materials may require pressure assist to properly feed the pump.

- Monitor the material’s temperature. While controlled warming can reduce viscosity and improve flow rate, you need to ensure that the material is being dispensed within the appropriate temperature range.

- Match the pump type to the application. High pressure, high volume, and precision metering require different pump technologies.

- Choose the right size power ratio. Excessive pressure increases wear and air consumption, but insufficient pressure causes starvation and surging.

- Inspect seals and wetted components regularly. High-viscosity materials can accelerate wear and tear and shorten maintenance intervals.

- Minimize hose length when possible. Long hoses can increase friction losses and require higher pressure to maintain flow.

- Check for air intrusion. Even small leaks on the suction side can introduce air pockets that destabilize output.

- Avoid unnecessary inlet filters. High-viscosity materials can clog fine filtration quickly and restrict flow.

- Stabilize your air supply. In pneumatic systems, inconsistent air pressure directly impacts output consistency.

- Validate performance over a full production run. High-viscosity systems may appear stable in short tests but drift as material conditions change.

If you are experiencing issues and these tips are not helping, we provide local dispensing equipment maintenance as well as technical consultations.

The Best Pumps for High Viscosity Fluids

If adhesive dispensing is not your area of expertise, we want to help. With years of experience in the dispensing industry, we have helped manufacturers in different industries choose the best industrial pumps for high viscosity fluids for their particular needs.

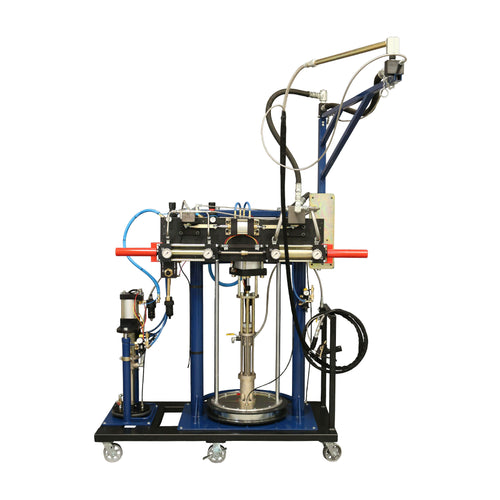

The HG 523 high-viscosity dispensing equipment is a top choice meant for two-component, super high viscosity fluids and is compatible with a material viscosity from 15,000 to 1,800,000 cP. It has a 62.5:1 power pump ratio for easy dispensing even when working with ultra-high-viscosity materials. It is also available in 5-gallon x 5-gallon or 55-gallon x 5-gallon setups.

Another option for a pump for high viscosity fluids is the Little Bear compact dispensing system. Its space-saving design and pneumatic setup make it ideal for restricted workspaces or on-site work. It is commonly used for dispensing two-part silicone sealants for glass glazing applications, but it can be used with acrylics, epoxies, MMAs, and more, depending on the configuration.

Need More Help?

High viscosity fluids can pose a challenge for dispensing systems, but they are not impossible to work with. Pumping high-viscosity fluids successfully comes down to understanding your material and engineering the system around it.

If you are having trouble dispensing high-viscosity materials or have more questions about a particular high-viscosity pump, we want to help. Contact us, and we will connect you with a dispensing expert.