Selecting the correct silicone structural glazing (SSG) sealant is critical for curtain walls, storefronts, and high-rise façade projects. GE UltraGlaze™ 4600 and GE UltraGlaze™ 4650 are two top-performing SSG sealants, each with unique properties.

Our team reviews the differences between UltraGlaze SSG4600 and UltraGlaze SSG4650, including their properties and preferred applications. We also throw in a few dispensing tips to ensure optimum results.

GE UltraGlaze™ 4600 Details

GE UltraGlaze™ 4600 is a two-part silicone elastomeric sealant and adhesive with a lot of flexibility. It provides strong adhesion to several types of coated glass, glazing gaskets, metal finishes, setting blocks, and spacers, usually without the need for a primer. With a great balance of strength and flexibility, it's primarily formulated for structural glazing applications. The UltraGlaze SSG4600 sealant is also a weatherseal product for joints that do not exceed its movement capacity of ±25%.

Other key properties:

-

Non-sagging

-

Resistance to tearing

-

Resistance to water immersion

-

Resistance to weathering

-

Resistance to ultraviolet radiation

-

Resistance to heat up to 300°F

-

Cyclic movement capacity ±25%

-

99% elastic recovery

GE UltraGlaze™ 4650 Details

GE UltraGlaze™ 4650 is a two-part silicone elastomeric sealant and adhesive for structural glazing applications. It is commonly used in factory glazing, curtain wall units, unitized module systems, panelized module systems, and protective glazing. The UltraGlaze SSG4650 sealant can provide primerless adhesion to many substrates and has great weather resistance.

Other key properties:

-

Non-sagging

-

Resistance to tearing

-

Resistance to water immersion

-

Resistance to weathering

-

Resistance to ultraviolet radiation

-

Resistance to heat up to 300°F

UltraGlaze 4600 Vs. UltraGlaze 4650

While both sealants are similar and used in overlapping applications, there are differences to consider when choosing the right material for your project. Our team outlines some of the key similarities and differences between the UltraGlaze SSG4600 silicone and the UltraGlaze SSG4650 silicone below.

|

Property |

UltraGlaze SSG4600 |

UltraGlaze SSG4650 |

|

Chemistry |

Two-part, silicone elastomeric adhesive/sealant |

Two-part, silicone elastomeric adhesive/sealant |

|

Consistency |

Non-sagging |

Non-sagging |

|

UV Resistance |

Excellent |

Excellent |

|

Weather Resistance |

Excellent |

Excellent |

|

Work Life |

20-90 minutes |

20-65 minutes |

|

Hardness (ASTM D2240) |

40± |

40-45 |

|

Tear Strength |

64 ppi |

64 ppi |

|

Tensile Strength |

192 psi |

206 psi |

|

Shear Strength |

124 psi |

137 psi |

|

Elastic Recovery (ISO 7389) |

99% |

|

|

Cyclic Movement Capacity |

±25% |

|

|

Ideal Applications |

Structural glazing, protective glazing, and weather sealing |

Structural glazing and protective glazing |

**Always consult each product's technical datasheet for project-specific guidance.

Both sealants share the same base chemistry as two-part silicones that are non-sagging and can be used as adhesives or sealants. They also both boast excellent resistance to UV radiation and weathering. Combined with their great strength, the UltraGlaze SSG4600 silicone and the UltraGlaze SSG4650 silicone are both made for structural glazing applications.

While similar in many ways, there are some important differences between the UltraGlaze SSG4600 silicone sealant and the UltraGlaze SSG4650 silicone sealant. To start, SSG4600 offers a slightly longer work life (20-90 minutes) compared to SSG4650 (20-65 minutes).

Strength and flexibility are other important differentiating factors. While both sealants have the same tear strength, UltraGlaze SSG4650 has a slightly higher tensile and shear strength than the SSG4600. That being said, the UltraGlaze SSG4650 lacks the flexibility of the UltraGlaze SSG4600. The GE UltraGlaze SSG4600 silicone has an impressive elastic recovery of 99% and can handle cycle movement of ±25%. This flexibility makes the UltraGlaze SSG4600 suited for weather sealing applications with joint movement.

Application & Dispensing

Whether you choose the UltraGlaze SSG4600 or the UltraGlaze SSG4650, you need to ensure you apply it correctly. Especially if your application involves cyclic movement or more extreme environmental conditions, the sealant needs to reach its optimum performance. Even the most durable sealant can fail if the beads are inconsistent, the joints do not have enough sealant, or air pockets arise during installation.

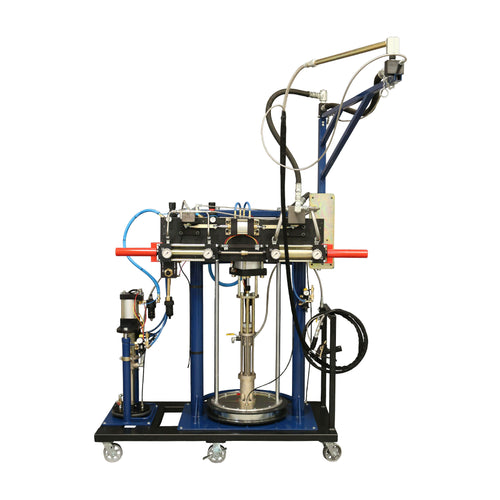

Semi-automated dispensing systems help ensure consistency and precision. They can also drastically improve efficiency over manual caulking guns. The HG 437 sealant dispensing system, for example, is designed for high-production structural glazing applications. On the other hand, the HG LB sealant dispensing system may be a better choice if you do not require such a high volume.

Along with using the right equipment, you will also want to ensure proper surface preparation. While both sealants offer primerless adhesion in many cases, you will still want to follow the recommended processes outlined on the product's technical datasheet.

Talk to the Experts

Choosing correctly between the UltraGlaze SSG4600 and the UltraGlaze SSG4650 and applying it properly can make all the difference in your project's performance.

At Dispensing.com, we can help with the dispensing and application of both materials. We carry a selection of silicone structural glazing sealant dispensing systems that are designed with these materials in mind and can also provide guidance on how to optimize your dispensing processes. Just contact us for more help.

Hotmelt.com is not affiliated with UltraGlaze™. UltraGlaze™ is a trademark of GE.