- SSG Sealants

- Sealants

- Silicones

- Glass Glazing

- Insulated Glass Glazing

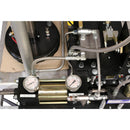

Dual-Component Silicone Dispenser for Glazing Applications in the Field

A dispensing system for retrofit and on-site window glazing applications, this equipment dispenses two-part silicone sealants from paired 5-gallon pails with precision and control. It has a lightweight, all-aluminum frame and is fully pneumatic for portability. Coupled with its compact design, this system is a top choice for dispensing equipment for swing stage applications specifically when space is restricted and weight needs to be minimized.

While portable and lightweight, this machine can still handle high-viscosity materials in fixed 1:1, 2:1, 4:1, and 10:1 ratios for consistent and efficient dispensing.

Key Advantages

- Perfect Dispenser for Scaffolding/Swing Stage Applications: With a lightweight aluminum frame, this system is built for elevated and space-constrained glazing environments.

- Fixed-Ratio Versatility for Compatibility with Several Materials: This system can be factory-configured to 1:1, 2:1, 4:1, 10:1, or other required mix ratios.

- Compact Pail-Based Setup for Ease of Use: Dispensing directly from two 5-gallon pails, this portable silicone glazing dispenser is ideal for jobsite mobility and efficient material use.

- All-Pneumatic Operation for Remote Work Environments: Because no electricity is required, you can ensure safe and dependable use on scaffolds, swing stages, or other remote setups.

- Consistent Output for Reliable Work: Flow rates up to 0.65 gallons per minute, depending on material and configuration.

- Equipped with Wheels for Easy Mobility: Built-in mobility makes transport and repositioning easy on the jobsite or in shop settings.

- Made in the USA: This equipment is engineered with high-quality components and made in the USA.

Technical Specifications

- Model: HG SB ("Skinny Bear")

- Adhesive Compatibility: 2-Part Adhesives

- Fixed Ratio Options: 1:1, 2:1, 4:1, 10:1 and Everything Else

- Container Size: (2) 5 Gallon Pails

- Material Viscosity Range: 15,000 - 1,800,000 cps

- Flow Rate: 0.20 - 0.65 Gallons per Minute (varies by viscosity)

- Pump Power Ratio: 43:1 Catalyst, 43:1 Base

- Air Compressor Requirement: 30 Gallon Minimum, 4 CFM Minimum

- Hose Length: Up to 50 Feet

- Dimensions: 43" L x 25" W x 48" H

- Weight: 348 lbs

Customizable Options Available

This dispensing system is for retrofit glazing and on-site installation work primarily, but it can be fitted with a variety of customizations to meet your specific needs.

- Fixed Ratio Configuration: Factory-set to 1:1, 2:1, 4:1, 10:1, or other required ratios

- Hose Lengths: Custom lengths available up to 50 feet

- Applicator Type: Choose from high-output or precision metering guns depending on your application

Contact us to configure the system for your workspace, material ratio, and field setup.

Compatible Materials

This system is ideal for dispensing high-viscosity, two-part structural sealants used in window glazing and curtainwall applications. Some compatible products include:

- Dowsil 983 and Dowsil 993

- Tremco Proglaze II

- GE UltraGlaze 4600 and GE UltraGlaze 4650

- Sikasil SG-450 and Sikasil SG-500

- Pecora 985

- Fenzi 10:1 Poly Sulfide Sealant

- Other 2-part silicones, polysulfides, and urethane-based sealants used in facade and retrofit projects

Submit the form below to get the Technical Data Sheet (TDS) for HG SB sent to your email address.

Questions about HG SB? Our team of adhesive specialists can help. Submit your questions and we'll get you answers right away.