Table of Contents

- Warehouse Glazing Dispensing Systems

- Field Glazing Dispensing Systems

- Warehouse vs. Field Glazing Dispensers

- Choosing the Right Glazing Dispenser

- When to Choose a Warehouse Glazing Dispensing System

- When to Choose a Field Glazing Dispensing System

When it comes to glass glazing, choosing the right dispenser is crucial. The right system can not only improve your efficiency but also make the work itself a lot easier. One key factor that can impact which tool you need is your work environment.

Some dispensing systems are best for warehouse or factory settings, while others may be better suited for field glazing applications. It is not always obvious which is which, so our team is here to help.

We break down some of the key differences between warehouse glazing dispensers versus field glazing dispensers. This comparison can make it easier to determine what dispensing equipment is best for your specific application. We also share a few recommendations for dispensers tailored to these different environments.

Warehouse Glazing Dispensing Systems

Warehouse or in-house glazing dispensers are usually designed with high-volume applications in mind, like in factories or production lines. They excel in efficiency and repeatability in controlled, large-scale operations. Dispensers for glazing in-house are also often bigger in size and may lack some features that make them easily portable.

Key Benefits:

-

High level of efficiency

-

High throughput and volume

-

Repeatable and precise material dispensing

-

Industrial-grade construction for heavy use

-

Compatible with automated or semi-automated systems

-

Reduced material waste and downtime

Field Glazing Dispensing Systems

Field glazing dispensing systems are high-volume dispensers that are designed for on-site applications where portability and flexibility are essential. They usually have features such as wheeled bases, pneumatic power sources, and compact or lightweight designs to make them easy to maneuver and set up in tight or variable workspaces.

Compared to factory glazing dispensers, these mobile glazing equipment systems are better suited for less controlled environments, such as construction sites or outdoor installations. They are also far more efficient and productive than manual dispensers, such as cartridge guns, as they provide consistent material flow and faster application.

Key Benefits:

-

Lightweight and space-saving designs

-

Portable and mobile dispensing

-

Reliable and efficient operation in more challenging work environments

-

Compatibility with outdoor settings

-

Higher efficiency and productivity than manual dispensing

Warehouse Vs. Field Glazing Dispensers: Key Differences

While there can be a lot of overlap, warehouse dispenser systems are generally built for high-volume factory environments, and field dispensers are designed for on-site use, with portability and flexibility taking priority.

Our team highlights some of the differences between factory and field glazing dispensers so you can better understand their key features and choose the right system for your project.

|

Feature |

Warehouse Dispensers |

Field Dispensers |

|

Typical Environment |

Controlled, factory/warehouse |

In the field/variable jobsites |

|

Design |

Industrial-grade construction, may be bulky |

Compact, lightweight |

|

Volume |

High-volume dispensing |

Medium- to high-volume dispensing |

|

Portability |

May or may not have wheels |

Usually a wheeled base |

|

Power source |

May be electric or pneumatic |

Often pneumatic |

Choosing the Right Glazing Dispenser

Selecting the right dispensing equipment depends on your specific project requirements. We have worked in the dispensing industry for many years and understand the nuances that go into choosing the right system for the specific job.

While there is not a hard line between what is considered a warehouse adhesive dispensing system and a field adhesive dispensing system, many dispensing machines are designed with one environment more in mind.

When picking a dispenser, you should consider:

-

Job environment

-

Volume

-

Mobility requirements

-

Adaptability

-

Budget

When to Choose a Warehouse Glazing Dispensing System

-

Your priority is high-volume dispensing.

-

You are looking for durability and industrial-grade construction.

-

You want an automated or semi-automated system.

-

You do not need a system that is easily transported.

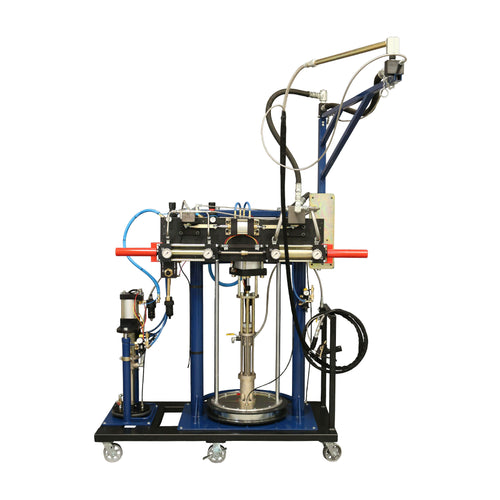

What We Recommend & Why: HG 437 Industrial Strength Sealant Dispenser

For factory glazing, this dispenser is an excellent choice. It delivers a consistent and efficient performance with a high output for high-speed production. It can dispense directly from a 55-gallon drum and a 5-gallon pail. This factory glazing dispensing system also has a wheeled base and is pneumatically powered for easy movement around production floors.

When to Choose a Field Glazing Dispensing System

-

You are looking for a compact design that can work in space-restricted job sites.

-

You need equipment that is portable and mobile.

-

You want adaptability for changing work environments.

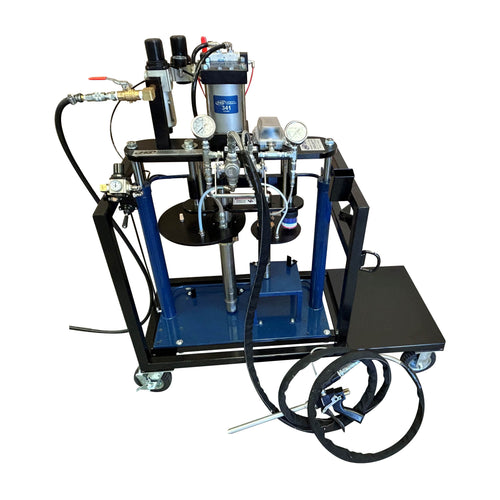

What We Recommend & Why: HG Little Bear Silicone Dispenser

With a compact design, wheeled base, and all-pneumatic power source, this structural glazing field dispenser is great for a wide range of jobsites, including those that may be more off the grid. Although it is smaller in size, it can still support a flow rate of up to 0.65 gallons per minute, depending on material viscosity, and is drastically more efficient than any manual dispensing option. This system can also be used in factory settings, but it does not support as high a volume as some other options.

**If you are doing retrofitting for high rises or on-site window glazing up high, there is also a silicone dispenser for swing stage or scaffolding dispensing applications specifically that we recommend.

See What Works for You

Whether you're working in a controlled warehouse environment or regularly going off the grid for jobsites, you need a dispenser that will best meet your specific needs.

You can explore our full collection of glass glazing dispensing systems that includes both warehouse glazing dispensing systems and field glazing dispensing systems, or you can talk with our team. They are happy to answer your questions and offer guidance on your product selection.