Table of Contents

- What Is Structural Glass Glazing?

- Types of Structural Glazing

- Advantages

- Limitations

- Most Popular Materials Used in Structural Glazing

- Glass Glazing Dispensing & Application

- FAQs

Structural glass glazing has become a popular feature of modern architecture. From sleek commercial facades to expansive curtain walls, structural glazing is not only aesthetically pleasing but also has to be structurally sound.

As experts in the adhesive and sealant dispensing space, we break down how glass glazing works, its pros and cons, and application tips. Our team also looks at how these systems are applied in real-world projects and what factors matter most when determining materials and dispensing equipment.

What Is Structural Glass Glazing?

Structural glass glazing is an architectural approach where glass panels are bonded directly to a building’s frame using structural sealants or adhesives instead of mechanical fasteners. This method creates a modern appearance and pleasing aesthetic with larger glass panels and minimal framing.

Beyond promoting an aesthetic design, structural glazing also provides structural support to the building. The bonded joint transfers wind, thermal, and seismic loads from the glass into the supporting structure. Consequently, the joint must be strong enough to handle the load and flexible enough to withstand movement.

Structural glazing is commonly used in curtain wall systems, skylights, storefronts, and other architectural features where transparency and daylighting are key design goals.

Types of Structural Glazing

There are also multiple structural glazing configurations, each designed to balance aesthetics, performance, and safety. The system you should choose will depend on building design, load requirements, and the environment.

Four-sided glass structural glazing

In four-sided structural glazing, the insulated glass unit is bonded with structural silicone to the surrounding mullions or framing members on all four edges. This design creates a seamless, frameless appearance. It is common in high-end curtain wall applications.

Two-sided structural glazing

In two-sided glazing, glass is structurally bonded on vertical edges and mechanically retained on the top and bottom. This setup adds redundancy while preserving a clean look.

Unitized structural glazing

With unitized glazing, the glass panels are bonded to frames in a factory and delivered as complete units. This can improve quality control and speed up installation.

Stick-built structural glazing

With stick-built glazing, components are assembled and sealed on site. This method allows flexibility for complex building geometries.

Point-supported or spider glazing

In this type of glazing, glass panels are supported by discrete fittings rather than continuous frames. This type of design can maximize transparency in feature walls and entrances.

Advantages

Structural glass glazing continues to gain traction in commercial and architectural projects because of its clear benefits.

With the proper design, material, and installation, the benefits of structural glazing include:

- Aesthetically pleasing and clean design with larger glass surfaces

- Increased natural light

- Flexibility in design that is not limited by frame size or glass weight

- Better energy efficiency and insulation

Limitations

Despite the benefits, structural glass glazing does have its limitations, and it is not the best option for every application.

Some potential limitations of structural glazing include:

- More complex installation and reliance on skilled labor

- Higher upfront cost

- More complicated maintenance and repairs

Most Popular Materials Used in Structural Glazing

Structural glazing materials must meet strict performance and safety requirements, especially in commercial construction.

Some commonly used weathersealing and structural silicone glazing materials include:

- DOWSIL 983

- DOWSIL 993

- Tremco Proglaze II

- GE UltraGlaze 4600

- GE UltraGlaze 4650

- Sikasil SG-500

- Sikasil SG-450

- Pecora 985

The right material for you will depend on your specific application. Different structural silicone glazing sealants have varying strength, flexibility, working times, and environmental resistance. It is important to review the technical datasheets for these materials to ensure the one you choose is compatible with your requirements or to work with an expert on your selection.

Glass Glazing Dispensing & Application

The material is only as good as its application. Weathersealing and silicone structural glazing materials require precision and consistency. Bead size, bead placement, and proper curing will all influence the long-term performance of these materials, and failure can be detrimental.

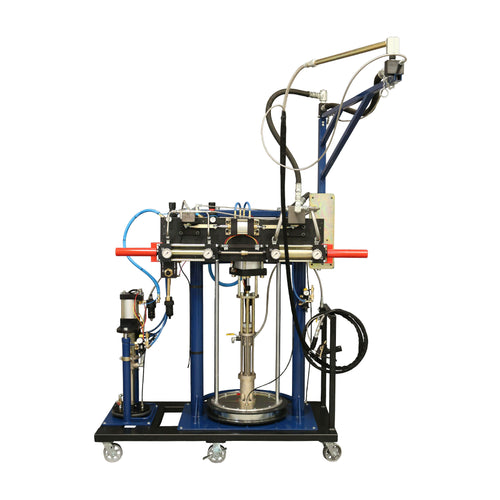

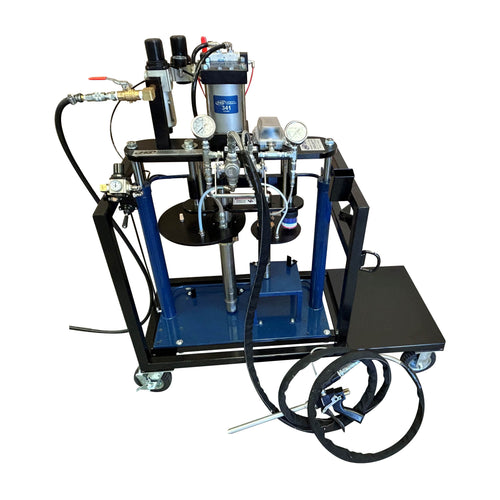

Consequently, choosing the right dispensing equipment matters, especially for high-volume applications. We have worked with manufacturers doing glass glazing both in the field and in their warehouse. The dispensing equipment for structural glazing you choose should be based on the specific application, material, production volume, and environment, but we have a few suggestions.

Some structural glass glazing dispensing systems we recommend researching further are below.

- For unitized glazing: HG 437 silicone dispensing system

- For field glazing: LB compact silicone dispensing system

- Rework glazing: HG SB scaffolding and swing stage dispensing system

Other helpful tips for the application and dispensing of structural silicone glazing sealants include:

- Read the manufacturer’s instructions for best practices for application, surface preparation, and storage.

- Follow proper cleaning and preventative maintenance measures to ensure the long-lasting and effective performance of your equipment.

- Bonded units should have time to develop their strength before being exposed to stress.

- Inspect the finished unit to ensure proper dispensing and application.

Equipment Needs?

Structural glazing requires the right design, material, and application. If you are looking for more information about the equipment you need, we want to help. We have a collection of dispensing systems for structural glazing you can explore. You can also contact our team and speak with an expert to find the right dispensing system for your needs.