Table of Contents:

- Single-Acting Pump Pros and Cons

- Double-Acting Pump Pros and Cons

- Differences Between Single-Acting and Double-Acting Flow

- How to Choose for Dispensing

- Application Recommendations

When it comes to adhesive dispensing, using the right equipment for your application matters, and a big part of how the equipment works is based on its pump and flow. The correct pump can lead to more consistent results, better precision, or improved efficiency. The wrong pump can lead to poor performance, aesthetic issues, or bond failure.

Two common pumps in dispensing equipment are single-acting and double-acting pumps. Each has its own strengths and weaknesses, so understanding the differences between them can help you select the right type of pump for your specific dispensing application.

Our team reviews the differences between single-acting and double-acting pumps in dispensing systems, as well as when to choose each.

Single-Acting Pumps

Single-acting pumps dispense adhesives and other materials on only one stroke of the piston. Usually, the adhesive is dispensed on the forward stroke while the return stroke is used to reset the piston and recharge or draw more material into the chamber.

Pros

If you are thinking of purchasing one of these products, there are several benefits of single-acting flow dispensers.

-

Simple Design- Single-action pumps usually have fewer components and moving parts. For contractors especially, this simple design may be easier to use.

-

Precise- Single-acting pumps do metered shots, so they can dispense the exact same amount of material in the exact same place over and over again.

-

Lower Cost- Because of their simple design, these machines are usually less expensive. They also usually require less maintenance, which can quickly add to the cost.

Cons

While there are many pros, there are also some potential cons of single-acting pumps in material dispensers.

-

Lower Volume- The biggest downside to single-acting pumps is that they are not as well-suited for high-volume applications. They only dispense on one stroke, and the recharge can take about two seconds.

-

Inconsistent Dispensing- These pumps may lead to a bit of inconsistency in dispensing throughput. There can be a little bit more material dispensed at the very first part of the shot from pressure buildup.

Double-Acting Pumps

Double-acting pumps, also called dual-acting pumps or continuous flow pumps, dispense adhesive on both the forward and return strokes of the piston for a more continuous flow. Each side of the chamber has a filling point and an outlet, so it is able to fill from both sides and dispense from both sides. As one side of the chamber is being pumped with material, the other side is dispensing material. The roles switch as the piston moves in the other direction.

Pros

We outline some of the most important benefits of choosing a dispensing system with double-acting flow below.

High Volume- Since double-acting pumps dispense on both the up and the down stroke, they can dispense high volumes of material more easily.

Efficient- Because they have a higher throughput and faster cycle time, double-acting hydraulic pumps can improve efficiency in high-volume dispensing applications.

Consistent Amounts- Double-acting pumps have a very short recharge time and consequently have a more continuous output (hence the term continuous flow), so the material is dispensed evenly throughout. For visible applications, this consistency can be an important part of the product's aesthetic.

Cons

There are also potential downfalls of double-acting pumps.

More Expensive- Because they have a more complex design, dual-acting hydraulic pumps tend to be more expensive than single-acting pumps and may require more maintenance.

Less Precise- Unlike single-acting pumps that can do metered shots, double-acting pumps are harder to set specific, repeatable dispensing amounts.

What Is the Difference Between Single- and Double-Acting Pumps?

Not only is it helpful to know the pros and cons of each pump, but also it is important to understand the differences between them. To help you better compare single-acting and dual-acting flow pumps, our team created the chart below.

| Feature | Single-Acting | Double-Acting |

| Dispensing Pattern | on one stroke only | on both the forward & return stroke |

| Recharge Time | about two seconds | almost none |

| Precision | can do metered shots | not designed for specific, repeatable dispensing amounts |

| Dispensing Consistency | can have small inconsistencies | consistent throughput |

| Complexity | simple design, less maintenance | can be more complicated & involved |

The biggest difference between single-acting and dual-acting flow pumps is how they dispense the adhesive. Single-acting hydraulic pumps dispense on one stroke while continuous-flow pumps dispense on two strokes. This setup also creates a difference in recharge time. While single-acting pumps have about a two-second recharge time between dispensing, double-acting pumps have such a minimal recharge time that they are sometimes called continuous flow pumps.

Other differences in double-acting and single-acting pumps are in their precision and consistency. Unlike dual-acting flow, single-acting pumps can easily be configured to do metered shots, so they have a higher level of precision when it comes to dispensing repeatable amounts. On the other hand, single-action pumps may dispense slightly more adhesive on the first part of the shot from pressure buildup, whereas double-acting pumps tend to dispense a consistent amount throughout.

Finally, the single-acting pumps do tend to be simpler in design than the double-acting pumps.

Choosing Between a Single-Acting Vs. Double-Acting Pump for Dispensing

It is important to not only understand the difference between single-acting and double-acting flow but also how those differences could be advantageous for your needs. When deciding between single-acting flow and double-acting flow for dispensing, it is important to consider the following factors:

-

Application- If the specific application calls for repeatable and consistent amounts, then single-acting flow control is better. If the application calls for more continuous flow, the double-acting pump may be a better option.

-

Volume- Higher-volume applications may benefit from using a double-acting flow dispensing system because more adhesive can be dispensed at a faster rate.

-

Aesthetic- Double-acting flow is better for applications when the adhesive is visible because the flow consistency is better. If the adhesive is not visible, then a single-acting dispensing machine may be able to do the job.

-

Precision needed- For more precise applications, a single-acting pump is better because it can be set to do metered shots.

Application Recommendations

When comparing single- versus double-acting pumps, one of the most important considerations is the specific application.

Single-acting flow dispensing systems- These systems are ideal for metered shots or fixed volumes. They can also be great for intermittent or lower-volume dispensing. Common applications for single-acting dispensing systems include electronic potting or expansion joint-sealing. Especially for businesses with a more limited budget, single-acting dispensing systems may be the way to go.

Double-acting flow dispensing systems- On the other hand, these systems are ideal for high-volume applications needing an uninterrupted, consistent flow. They are commonly used in electronic sealing, automotive assembly, or sealing aerospace panels.

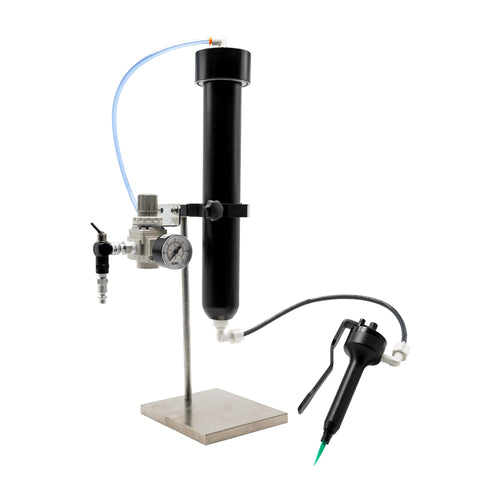

While one pump may generally be a better choice than the other for certain uses, the right choice will largely depend on the specific application. For example, double-acting flow systems, like the HG Big Bear 437 silicone dispenser, are frequently used for window glazing dispensing applications. While less common, there are some instances where the bead does not need to be continuous, and a single-acting dispenser may be preferred. In those cases, the CMP 632 portable dispenser would be the better choice.

Get an Equipment Recommendation

Using the right pump is pivotal in getting optimal efficiency and the best finished product. If you are not sure what type of dispensing system you need, do not fret. We have a team of experienced material dispensing experts and a wide range of dispensing systems available. We can talk about your material and application details to help guide you with a personalized equipment recommendation for your application.