August 22, 2025

In the glass glazing industry, adhesive application is critical to both performance and aesthetics. Whether you are field glazing a curtain wall or doing swing stage rework, the equipment you use can significantly impact the final product as well as your workflow.

When it comes to glazing applications, there are basically two options for dispensing: cartridge glue guns or meter mix dispense equipment. Our dispensing experts took a closer look at each type of equipment and broke down their pros, cons, and applications to help you determine which is best for your specific needs.

Cartridge Guns

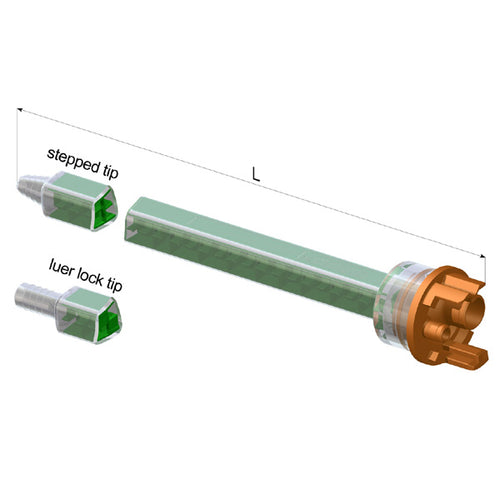

Cartridge guns are handheld tools used to dispense adhesives from cartridges. There are cartridge guns for both one-component and two-component adhesives. Cartridge guns can also be manual, pneumatic, or battery-powered. They are a popular choice for many businesses working out in the field or working on a smaller scale.

Pros

-

Portability- Some of the biggest pros of adhesive cartridge guns are that they are portable, lightweight, and take up minimal space.

-

Flexibility- Another benefit of a cartridge glue gun is that it is versatile and can easily be used for various dispensing applications.

-

Simplicity- Compared to metering and mixing machines, glue cartridge guns are simple. They are easy to operate and require minimal training or maintenance.

-

Cost- Another big difference between adhesive cartridge guns and meter mix equipment is the upfront cost. Cartridge guns are much less expensive initially.

Cons

-

Inefficient- Especially if cartridges need to be changed out frequently, cartridge guns can significantly slow down production.

-

Fallible- Cartridge guns are much more prone to operator error, including dispensing inconsistent amounts that could even lead to bond failure.

-

Less Ergonomic- Especially with repetitive dispensing in higher volumes, cartridge guns can lead to operator fatigue and the risk of injury.

-

Higher Long-Term Costs- While the upfront costs are minimal, the long-term costs of cartridges can significantly add up and end up costing you more than the bulk option.

Browse our collection of two-component cartridge guns.

Meter Mix Systems

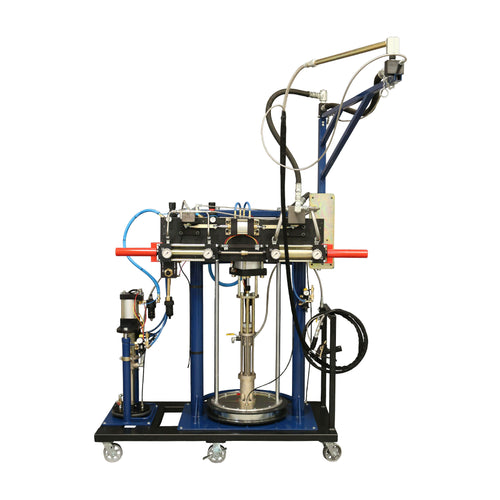

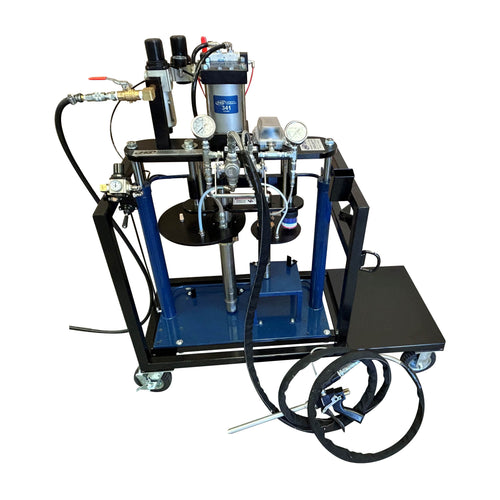

Meter mix systems are machines designed to accurately and efficiently blend and dispense two-part materials on a substrate. Meter mix systems can vary from large, industrial automated machines to simple benchtop dispensers.

Pros

-

Efficient- Compared to handheld adhesive dispensers, meter mix dispensing systems are highly efficient and great for continuous, large-scale production.

-

Fast- Meter mix systems can dramatically increase production speed and consequently, throughput.

-

Precise- With ratio monitoring and shot metering, these systems are accurate and precise. They can help significantly reduce the room for human error.

-

Ergonomic- These systems are designed to make dispensing easier for operators and reduce operator fatigue.

-

Lower Material Cost- Especially for higher-volume work, bulk adhesives are more cost-effective than cartridge equivalents.

Cons

-

High Initial Investment- While it may save you money in the long run, this equipment does come at a higher initial cost.

-

Some Maintenance Required- Every machine needs some amount of cleaning or maintenance.

-

Some Training Required- While many systems are still easy to use, they are more involved than cartridge guns and do require some amount of training.

-

Bulkier and Harder to Transport- Because they are larger pieces of equipment, they can be harder to transport around job sites. That being said, there are systems that are made to be portable and compact.

Browse our collection of meter mix dispensing systems for glazing.

Choosing Between Adhesive Cartridge Guns & Meter Mix Systems for Glazing

When comparing cartridge glue guns versus meter mix equipment for your glazing application, it is important to consider the following:

- Volume

- Speed

- Mobility

- Precision

- Application(s)

- Workspace

- Cost

Adhesive cartridge guns are best for glazing applications that are:

- Very small in scale and volume

- Slow speed

- Remote job sites or those with very limited space

- More likely to change frequently

In general, cartridge glue guns are better than meter mix systems for glazing applications that are very small in scale. They require minimal operator training and can easily be used in other applications.

While they are easy to use and transport, the accuracy and efficiency of the job will start to suffer as the work grows in scale. You should not rely on this type of equipment for growing operations.

Meter mix systems are best for glazing applications that are:

- Larger in scale or volume

- High speed

- Precise and need a high level of accuracy

- Done in a factory or warehouse

- High-volume field glazing

Compared to handheld cartridge glue guns, meter mix dispensing systems are better suited for industrial applications done at a larger scale. They can drastically improve speed and efficiency while removing a lot of human operator error.

While the equipment is bulkier and heavier than handheld cartridge guns, some machines are optimized for field work glazing. The HG Little Bear sealant dispenser, for example, is fully pneumatic, mounted on wheels, and has a compact design. There is even swing stage silicone dispensing equipment designed specifically with this very niche application in mind.

Find the Equipment You Need

There is no one-size-fits-all solution when it comes to dispensing glazing sealants. Cartridge guns may be a great choice for some. Others may reap great benefits from using a meter mix system instead.

Still not sure what equipment is right for you? Just contact us, and we can help point you in the right direction based on your unique needs and desires.