- Polyureas

- Unfilled Epoxies

- Unfilled Urethanes

Overview of the Epoxy Mixing & Dispensing System for High-Volume Floor Coating

If you're a professional or contractor applying epoxy coatings to concrete floors in busy environments like garages and warehouses, efficiency is key. The AST GMP 200P two-part dispensing system is specifically tailored to meet your needs, enabling you to complete jobs more efficiently without compromising on quality. This system is designed for those who demand top-notch results and want to optimize their workflow.

Using Epoxy Dispensing System vs Hand Mixing

Time is money, especially in the fast-paced world of professional and industrial epoxy applications. Traditional methods of hand-mixing and pouring epoxy are not only labor-intensive but also prone to inconsistencies, leading to costly rework. Using floor epoxy meter mix equipment eliminates these inefficiencies by automating the mixing and dispensing process.

With features like continuous flow up to 2 GPM and high fluid pressures, you can complete jobs in a fraction of the time it would take using manual methods. This means faster project turnaround, increased efficiency, and ultimately, more profitability for your business.

Key Features

High-Performance Pumping and Flow

Our system combines dual motor pumps with external lubrication and a continuous flow rate of up to 2 GPM. This ensures a smooth, consistent application every time, allowing you to complete your projects faster and more efficiently.

Precision and Flexibility

Achieve optimal adhesion with high fluid pressures up to 1,000 PSI and adjustable ratios ranging from 1:1 to 4:1. The manual dispense valve gives you full control for precise application.

Durability and Power

Choose between Stainless Steel or Plastic tanks with capacities of 8 ½ or 12 gallons, all powered by a robust 2 HP DC motor. The system is electrically operated at 220 volts, eliminating the need for manual pumping.

Versatile Material Compatibility

Our system is designed to pump non-abrasive materials, offering you greater flexibility in your choice of epoxy coatings.

Specifications

- Model: Portable

- Preset Ratio Range: 1:1 – 4:1

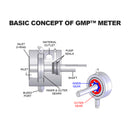

- Pumps: Positive Displacement AST Gear Metering Pumps

- Viscosity: 100 cps – 30,000 cps

- Drive System: 2 HP Electric

- Power Factor: 5:1, 10:1, 20:1

- Supply: 9 gallon plastic tanks (stainless steel optional)

- Shot Adjustment: 0-100% by adjusting motor speed

- Dispensing Manifold: Hand held; Automatic

- Continuous Output: Up to 2.0 gpm

- Controls: Electric Variable Speed 110/220v,

- Accuracy: 0.5% by volume (99.5% accurate)

- Hoses: Teflon core braided stainless

Common Compatible Materials

- Two-Part Epoxies

- ArmorClad Commercial Grade Epoxy System

- ArmorPoxy 100% Solids Epoxy

- Dur-A-Flex Dur-A-Chip System

- Dur-A-Flex Dur-A-Quartz System

- Duraamen Perdure HBE

- Duraltex 1705

- Duraltex 1805

- E-Chem EP-Clearseal

- E-Chem EP75-Seal

- E-Chem EP100 Seal LM

- E707HB High Build Epoxy

- Epoxy2U 100% Solids Epoxy

- Ghostshield Epoxy Max 100

- GlobMarble GE-100 Epoxy

- QuestMark 3707 High Build Epoxy Coating

- Resinwerks Bio-Cure EP 1100

- Resinwerks Kinetic

- Resinwerks Levelguard EP

- Resinwerks Novolac Epoxy

- Resinwerks Rapid H2O EP

- Resinwerks Vapor Barrier Epoxy

- Rust-Oleum Concrete Saver 6500 System

- Rust-Oleum Concrete Saver 8000S

- Shenandoah Paint V430

- Sherwin Williams Accelera 4850

- Sherwin Williams Resuflor 3746

- Sherwin Williams Resutile

- Sika Sikagard 170 CR

- Sika Sikagard 21

- Sika Sikagard 22

- Sika Sikagard 62

- Sika Sikagard 616

- Sika Sikagard 664

- Sika Sikalastic 350

- Sika Sikalastic 395

- Sika Sikalastic 720

- Sika Sikalastic 720 SG

- Simiron 1100SL

- Simiron 1150FC

- Simiron E-Flex

- Spartan Epoxies CLEAR100

- Stonhard Stonclad GS

- Stonhard Stontec Flake System

- Tennant Eco-HPS 100

- TK-EPOXY BRIDGE DECK OVERLAY 2109

- Watco High Build Epoxy 100 Anti-Slip

- Contact us to see if your material is compatible

Maintenance Video Resource

Downloads

Questions about AST GMP 200P? Our team of adhesive specialists can help. Submit your questions and we'll get you answers right away.